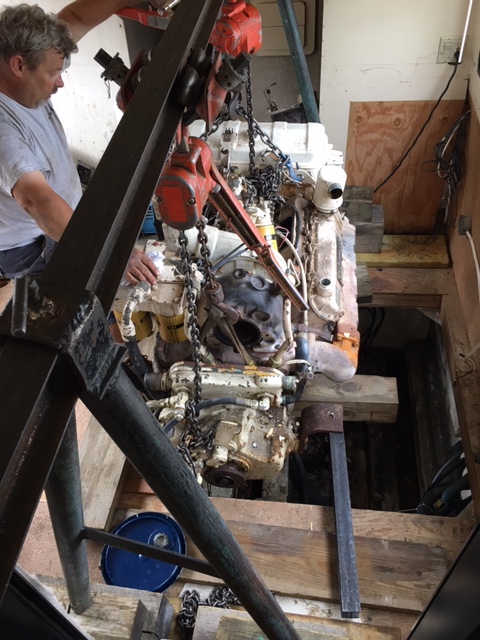

No, the engine is not back in the boat, the mechanic is still working on it as the components come back from the outside specialists. But we are making progress, while forward progress is slow, we are moving forward consistently. The big hurdle is completing the build out of the starboard engine and its reinstallation in the Lady’s engine room. Once that has been accomplished, the Lady will go back into the water for a sea trial to shake the new engine down and ensure that all is well with it. We will leave her in the water and move into a maintenance slip for the rest of our stay at the Gingerville Yacht Center.

The Port Engine diesel guy has informed us that things look promising with regard to his tasks and the engine looks well situated. We also asked him to replace the water pump impellor (it is on the bulkhead side of the engine and difficult to get to) and he is also going to replace all of the hoses to ensure that we have no mishaps with cooling hoses on our voyage home. In order for the mechanic to access those areas, we will have to remove the galley settee to open the third hatch in the galley floor. Which means the yacht center crew will have to pull the settee up and cut the covering fiberglass that is over the hatch. So, for the time that the port engine is being serviced, we will have three large square holes in our galley floor! Ain’t life grand?

All of our new appliances have been shipped and arrived! They are currently being stored in the yacht center’s warehouse until the engine work has been completed and the galley floors have been restored (hatches reinstalled).

Most of you have read of my ranting regarding responsiveness of the folks who do the majority of our work to refit the Lady into our vision for her eventual look. But we have had some really great interactions from some, certainly our electronics guy for one. He is always responsive and does a timely and efficient installation and check out of any work he does for us. Tomorrow, Friday the 15th, he will come down to the center and begin the process of installing and check out of the new digital yacht control system with integrates our GPS, Charting, Radar, AIS, VHF Radio and depth sounders into one comprehensive system. He will also install our satellite television antenna system so that when we are ready to move on board, the old Captain and his First Mate will not have to miss any more PGA golf tournaments. Other folks have also been timely and exceptional in their responsiveness.

Obviously I can’t say enough about the yacht center’s crew of specialists. They are always ready and willing to go the extra mile to ensure that the Lady is not wanting for anything from their perspective.

The diesel fuel in the Lady’s tanks had been in there for several years and was in need of “polishing” which is a term for filtering the fuel, agitating the fuel tanks and restoring the fuel to almost new fresh from the pump status, ergo the “polishing”. The company that was contacted to do this task called me back and scheduled an appointment (HORRORS. an actual appointment?) for 10 am on Thursday last week. At 10 am exactly, they arrived and began their work. Within a couple of hours, the approximately 300 gallons of diesel had been restored and my fuel tank was clean of any pollutants or particulates. YOWZA that’s what I am talking about. Can you imagine having to remove that much diesel and properly disposed of it, THEN having to fill the tanks with new fuel? Performing this diesel “polishing” was a true fuel saver for us. Lucky for us we only have to pump in about 200 gallons when we start our voyage home. Great service, professional demeanor, good job.

So based on that bit of good news, here is a funny happening regarding appliances for marine environments. The electric stove and dishwasher were removed when the boat was being prepared to pull the starboard engine and they were placed beneath the boat for storage, a large tarp was laid across them to protect from the elements.

Once the new appliances were delivered and stored in readiness, I decided it was time to get rid of the old stove and dishwasher. The refrigerator has already been given to one of the yacht center crew. There is a business entity here in this Annapolis suburb area that deals in consignment of boating equipment that the owners no longer want or need. This business basically takes in the items (sails, lines, power cords, you name it, they might have it). Rather than send the stove and dishwasher to the local landfill, it was thought that this consignment operation might be a place to take these items and let someone else get some use out of them for a very, very cheap price. So, I called these folks today and described what I had and that any price was acceptable because I really would rather see them reused than trashed. They did not want the dishwasher at all, but then I described the stove as a three burner, electric marine stove. The man on the phone said certainly, bring the item down and they has someone who could take it off the truck for me (my yacht broker loaned his large pickup truck).

A small note, today was in the high nineties and low one hundreds in temp and 80 or so for humidity, altogether a pretty crappy day to be out and about period.

I drove the stove over to the store, a member of the staff came out to the truck to look it over. Then they told me that they only handled propane stoves, so they couldn’t take my electric stove….. Bear in mind the old man has been out in the sun, heat and humidity for several hours at that point. So after a few choice sentences, I closed (gently) the tailgate on the pickup truck and left that establishment. Need I say that I shall never darken their doors again?

Upon arriving at the yacht center and parking near the Lady, I didn’t see anyone around who could help me with removing the stove from the truck, so, with the use of a boat hook I pulled the stove up to the tailgate and then shoved it off and onto the concrete. Guess it goes to the landfill now, huh?

Now one other little thing and I will let you go, as you may know our yacht came with a davit (marine lifting crane) and a dingy with an 8 horsepower Honda outboard motor. I noted that the dingy did not have a cover and was exposed to the elements. I bought a boat cover and an air pump and decided to cover the boat from these rainstorms. Turned out there was a lot of old water standing in it, the wooden floor had been water damaged and the float sides were showing leakage of the air. I asked the yacht center crew to remove the boat and check out the Honda engine, since it had been laying in the bottom of the water filled boat.

Turned out the motor was just fine, it started with the first pull of the starter cord. The boat itself however, was not so lucky. After taking the dingy to an inflatable boat dealer/repair show, it was shown to have a trashed transom and between that piece of wood and the floor, plus the labor involved in finding and repairing the four pin holes in the outer sections, the bill was just under 1500 dollars.

There was a new inflatable dingy in the showroom, that was the right size to replace our old damaged boat. The guy sold it to me for just about what it would have cost (estimated) for repairing the old boat and we would have a new dingy for the Lady. Made perfect sense to me and as a result, the Misty Lady has a brand new dingy with an integrated floor (no more plywood floor to get damaged), plus it has a warranty on the boat and all the attachments.

Yeppers, a new boat will rest in the cradle atop the Misty Lady!

We had a recommendation for a person to come to the Lady and reupholster the settee in the dining section of the galley. His name was Captain Canvas and he was reputed to be quite the character! Well, he missed our first appointment on Saturday, and called to apologize, saying he would be at the boat on Monday morning. After hanging around until after noon. I bagged it, telling the center owner that I was done with this guy. Turned out two days later, the yacht center guy who operates the huge TravelLift told me that Captain had committed suicide that Sunday. Oh great, now I felt really bad for all the rotten thoughts I had been thinking about his lack of attending.

Still rather unsettled over this, everyone was surprised saying that he was a strange person, a bit weird but a nice guy and very talented. One just never knows, do one?

Okay enough for now, we are hoping to have the new bridge canvas installed next week and the engine returned and installed next week and the sea trials done, finishing up with the reinstallation of the galley furniture ad the installation of the new appliances. THEN the Captain, the First Mate and the two Sea Cats will board the yacht and settle in. We will still be in this area for a while but will be out of the hotel and on our own yacht home!

Fingers Crossed? Thanks

the regular painting process.

the regular painting process.

This photo, just above, is a shot of the Misty Lady’s cabin Name Boards. There is one of these name board on each side of the boat, just below the bridge.

This photo, just above, is a shot of the Misty Lady’s cabin Name Boards. There is one of these name board on each side of the boat, just below the bridge.

![IMG_0120[1] IMG_0120[1]](https://i0.wp.com/mistylady.com/wp-content/uploads/2016/07/img_01201.jpg?w=416&h=555&ssl=1)

![IMG_0104[1] IMG_0104[1]](https://i0.wp.com/mistylady.com/wp-content/uploads/2016/07/img_01041.jpg?w=416&h=555&ssl=1)

Doesn’t she look rather sad just sitting on those blocks on DRY LAND? BTW the car sitting in the right foreground is our new GMC Terrain Denali small suv.

Doesn’t she look rather sad just sitting on those blocks on DRY LAND? BTW the car sitting in the right foreground is our new GMC Terrain Denali small suv.